Car hub bearings used to be used most in pairs of single row tapered roller or ball bearings. With the development of technology, car wheel hub unit has been widely used. Hub bearing units are increasingly used and used, and have now developed into the third generation: the first generation is composed of double row angular contact bearings. The second generation has a flange for fixing the bearing on the outer raceway, which can be simply put the bearing sleeve on the axle and fixed with a nut. Making car maintenance easier. The third generation of hub bearing unit is the use of bearing unit and anti-lock brake system ABS coordination. The hub unit is designed to have an inner flange and an outer flange, the inner flange is bolted to the drive shaft and the outer flange mounts the entire bearing together. Worn or damaged hub bearings or hub units can cause inappropriate and costly failures of your vehicle on the road, or even harm your safety.

Please pay attention to the following points in the use and installation of hub bearings:

1. In order to ensure maximum safety and reliability, it is recommended that you always check hub bearings no matter how old the vehicle is - be aware of any early warning signs of bearing wear, including any friction noise during rotation or abnormal deceleration of the suspension combination wheel during turns. For rear-wheel drive vehicles it is recommended to lubricate the front hub bearings until the vehicle reaches 38,000 km. When replacing the brake system, check the bearings and replace the oil seals.

2. If you hear the noise from the hub bearing part, first of all, it is important to find the location where the noise occurs. There are many moving parts that may produce noise, or some rotating parts may be in contact with non-rotating parts. If it is confirmed that it is the noise in the bearing, the bearing may have been damaged and needs to be replaced.

3. Because the working conditions of the front hub leading to the failure of bearings on both sides are similar, it is recommended to replace them in pairs even if only one bearing is broken.

4, hub bearings are more sensitive, in any case need to use the right method and appropriate tools. In the process of storage, transportation and installation, bearing parts can not be damaged. Some bearings require greater pressure, so special tools are needed. Always refer to the car's manufacturing instructions.

5. When installing bearings, they should be in a clean and tidy environment. Fine particles entering bearings will also shorten the service life of bearings. It is very important to keep a clean environment when replacing bearings. It is not allowed to hit the bearing with a hammer, take care that the bearing does not fall to the ground (or similar improper handling). Before installation, the condition of the shaft and bearing seat should also be checked. Even small wear will lead to poor fit, resulting in the early failure of the bearing.

6. For the hub bearing unit, do not attempt to disassemble the hub bearing or adjust the sealing ring of the hub unit, otherwise it will damage the sealing ring and lead to the entry of water or dust. Even the sealing ring and inner ring raceway are damaged, resulting in permanent bearing failure.

7. There is a magnetic thrust ring in the sealing ring equipped with the bearing of ABS device. This thrust ring cannot be affected by collision, impact or collision with other magnetic fields. Take them out of the box before installation and keep them away from magnetic fields, such as electric motors or power tools used. When these bearings are installed, the operation of the bearings is changed by observing the ABS alarm pin on the instrument panel through the road condition test.

8. Hub bearings equipped with ABS magnetic thrust ring. In order to determine which side the thrust ring is installed, a light and small thing can be used to close the edge of the bearing, and the magnetic force generated by the bearing will attract it. During installation, the side with magnetic thrust ring is pointed inward, directly towards the ABS sensitive element. Note: Incorrect installation may result in functional failure of the brake system.

9, many bearings are sealed, this kind of bearings in the whole life is not the need to add grease. Other unsealed bearings such as double row tapered roller bearings must be lubricated with grease during installation. Because the inner size of the bearing is different, it is difficult to determine how much oil to add. The most important thing is to ensure that there is oil in the bearing. If there is too much oil, when the bearing rotates, the excess oil will seep out. General rule of thumb: During installation, the total amount of grease should account for 50% of the clearance of the bearing.

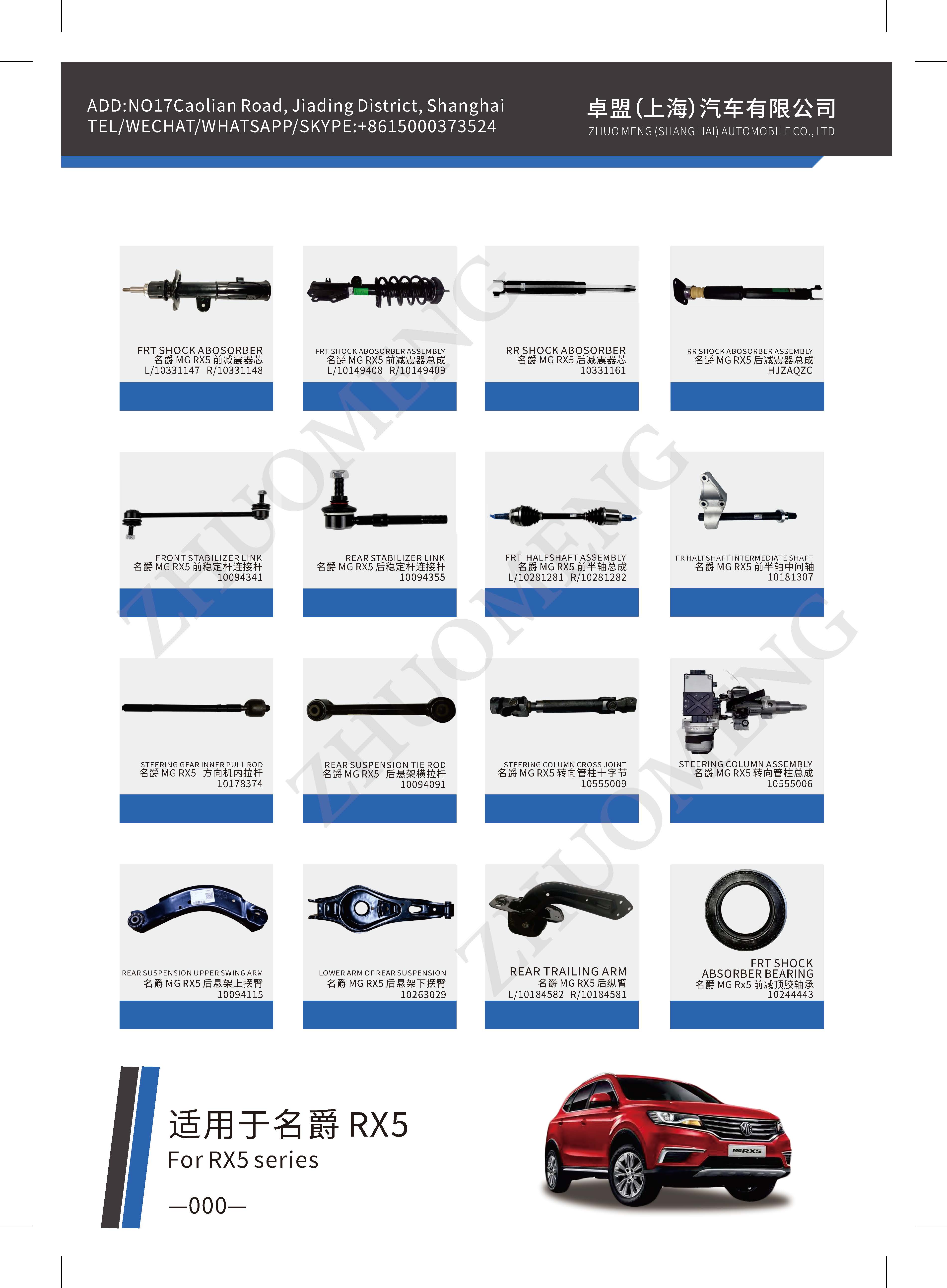

Atlas of automobile hub bearings

Automobile hub Bearing Atlas (5 sheets)

10. When installing lock nuts, the torque varies greatly due to the different bearing types and bearing seats